Sawing

We have outlined some basic guidance designed to assist you in converting your logs into the timber you need and to enable you to understand some of the terminology that you may come across when talking to service providers.

Cracking and Splitting

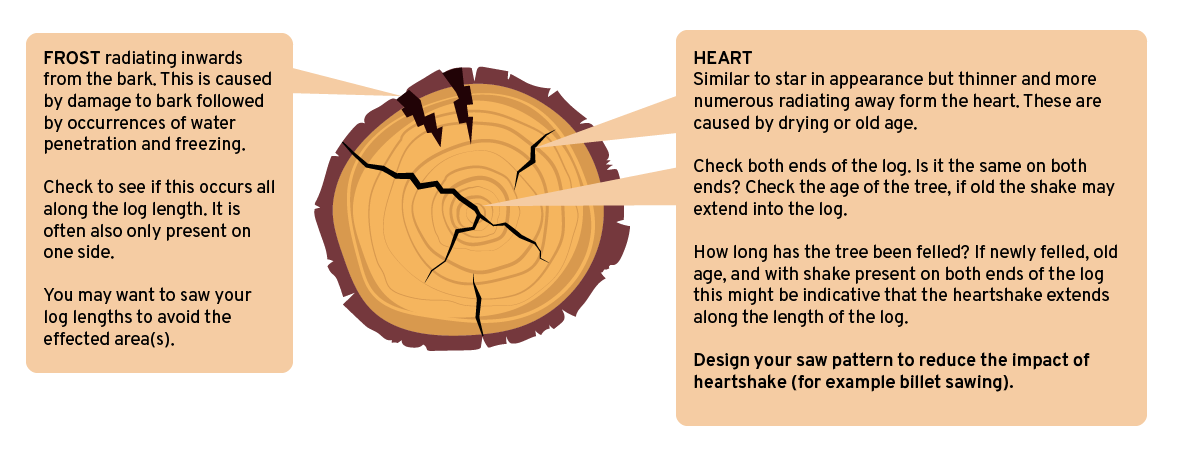

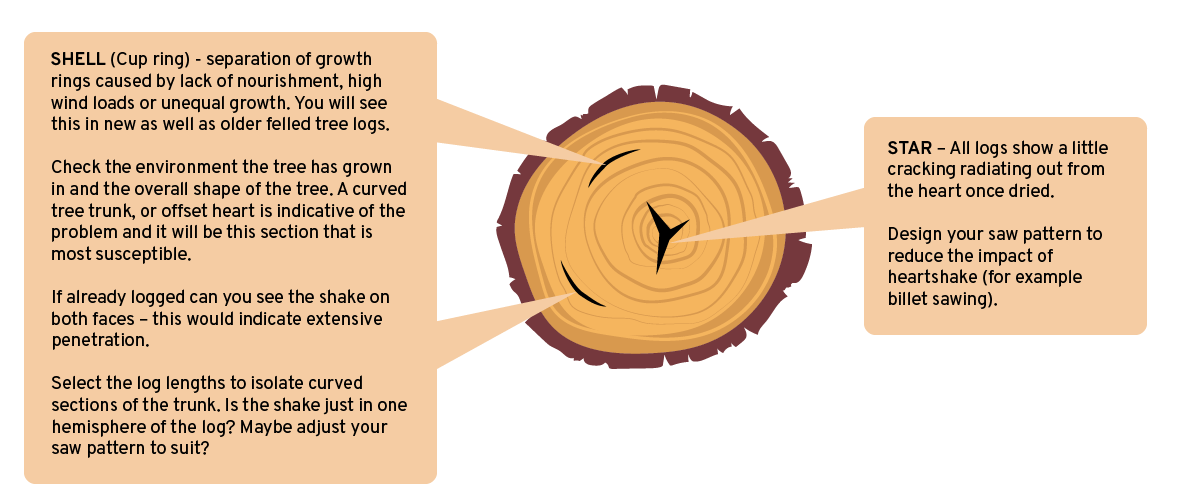

Cracking and splitting of sawn timber boards and beams is often initiated by the presence of “shake” in the logs. There are five major types; Star, Shell, Heart, Frost, and Thunder.

When boards and beams are dried the amount of cracking and splitting is often magnified, so its important to start with as little as possible.

For Star, Shell and Heart, when looking at a log face it is often very difficult to determine what extent the shake will be perpetuated along the length of the log. It may only extend for a few centimeters and the level of shake is magnified when the logs have dried for a while. So, if at all possible take some photos of the log ends as soon as the tree is felled and logged.

Types of shake and assessing them

Thunder Shake

Running across the grain and caused by shock (e.g. during felling).

Take care when felling (see tree surgery).

Look for cracking damage in the bark especially around areas where branches were.

Remove the bark in damaged areas to see if there are signs of Thunder.

Adjust your planned log lengths to remove sections effected by Thunder.

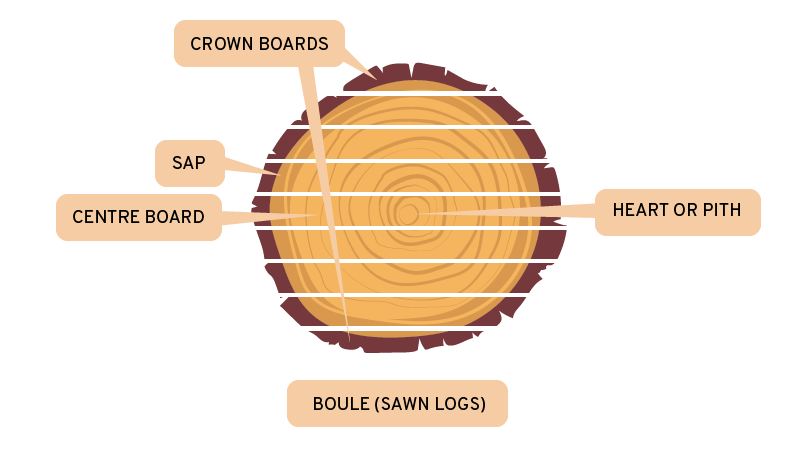

Sawing Boards - General Terminology

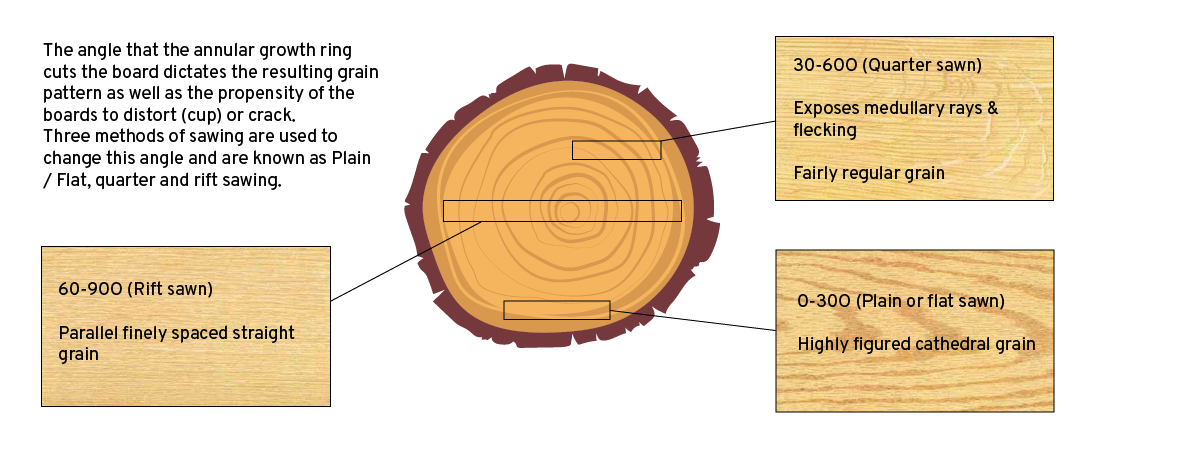

Generating Grain Patterns for Boards

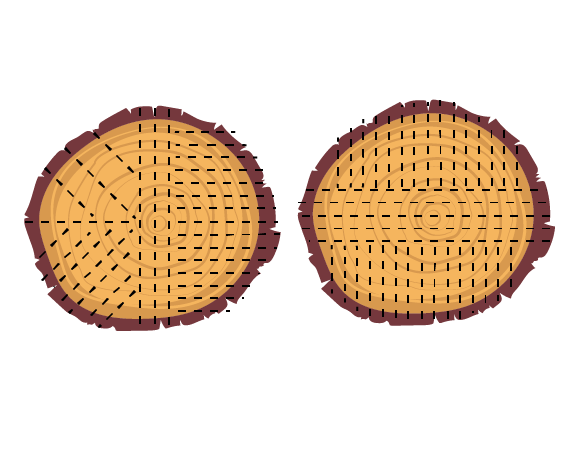

Plain (Flat) Sawing

Advantages:

- Lowest cost of sawing (relatively faster than quarter or rift).

- Produces a high level of figuring (although this may also be considered a disadvantage as the end user may want a straight grain).

Disadvantages:

- Boards (especially the crown) have a tendency to cup and crack during drying.

- High degree of figuring in boards which may not be wanted by some users.

- The centre boards are susceptible to heartshake.

- When sawing relatively thick boards there may (if the sap width is large) be a high degree of wastage.

Note: The centre boards are equivalent to being quarter sawn – the growth rings being almost perpendicular these are less prone to cupping and cracking and will have a straight grain pattern.

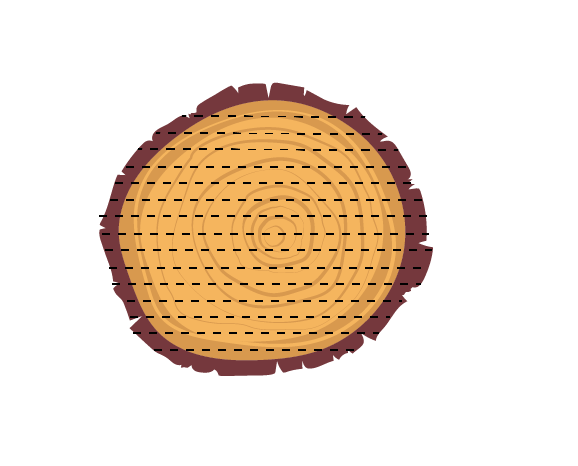

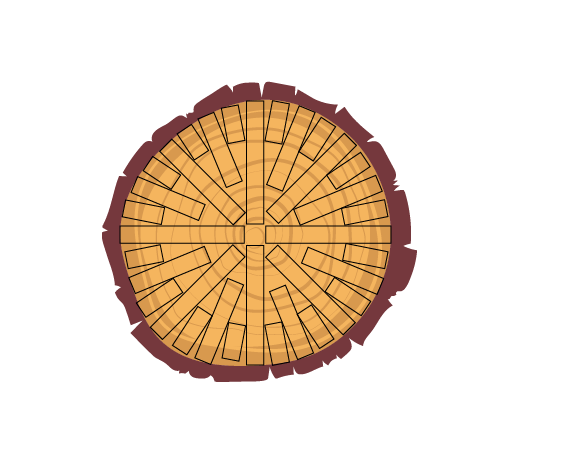

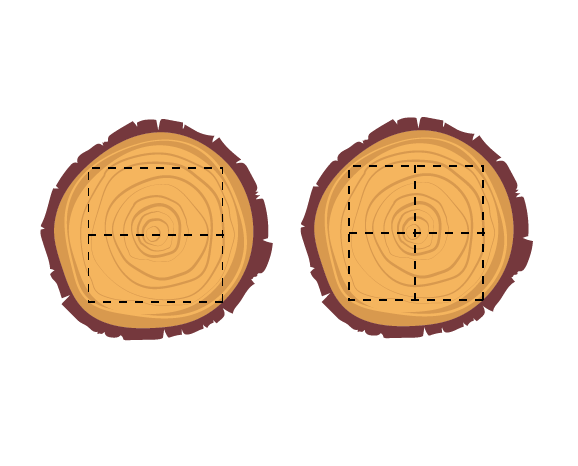

Billet Type Sawing Pattern

Minimising Cupping and Cracking

- Employ what is known as “billet sawing” (cutting log in half) – this relieves stresses and heartshake within the log.

- 2.If the boards will be kiln dried then season (in air) hardwood boards for a period of approximately 6 months (4 months for softwoods) for every inch (25 mm) of thickness. During the air seasoning ensure the boards are well weighted and supported to help prevent distortion.

- Fell and saw in the winter months.

- 4.Saw relatively thin crown boards.

(note above right is easier and less expensive to saw)

Quarter Sawing

Advantages:

- Stable and dries without excessive cracking.

- Exposes medullary rays and “flecking” in oak.

- Produces a more evenly spaced and straighter lines.

Disadvantages:

- Increased time (and expense) to saw

- Higher wastage than plane sawing.

- Larger diameter logs are generally required to avoid thin boards.

Note: Design the saw pattern to yield the boards you want.

Rift Sawing

Advantages:

- Extremely stable.

- Produces an evenly spaced parallel grain pattern

Disadvantages:

- The most time (and expense) to saw.

- The most volume wastage.

- Larger diameter logs are generally required to avoid thin boards.

Note: Design the saw pattern to yield the boards you want.

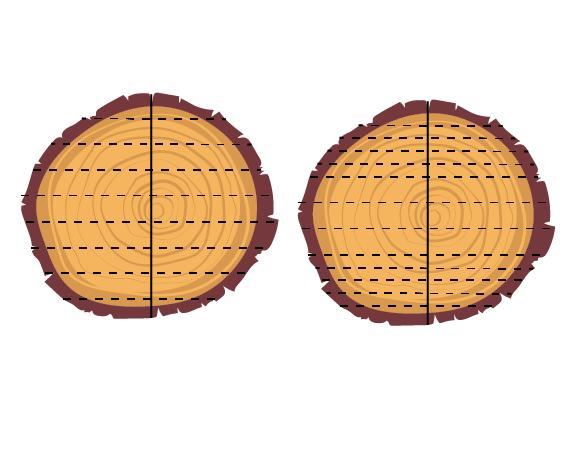

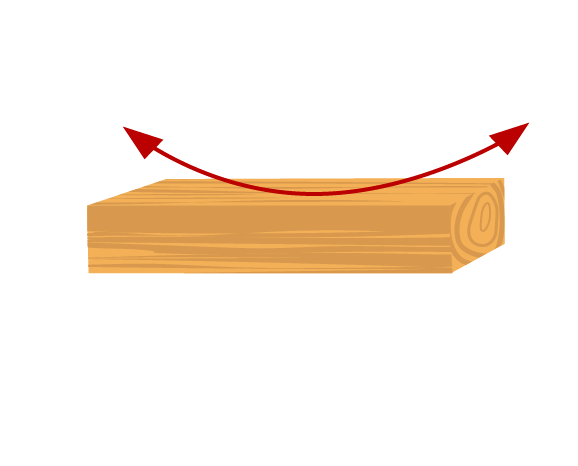

Sawing Beams

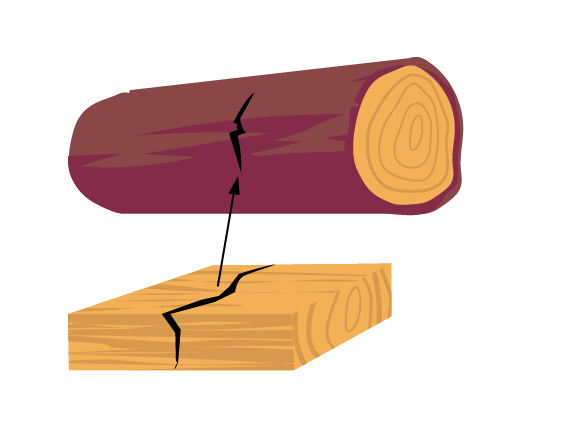

Producing a beam is all about balancing the residual tensile and compressive stresses within the log.

Although less important for short lengths (2 meters) for longer lengths this is critical.

The beam shown below will want to bow in the direction of the arrow. You can offset this by loading the beam in the opposite direction – but this needs a little thought!

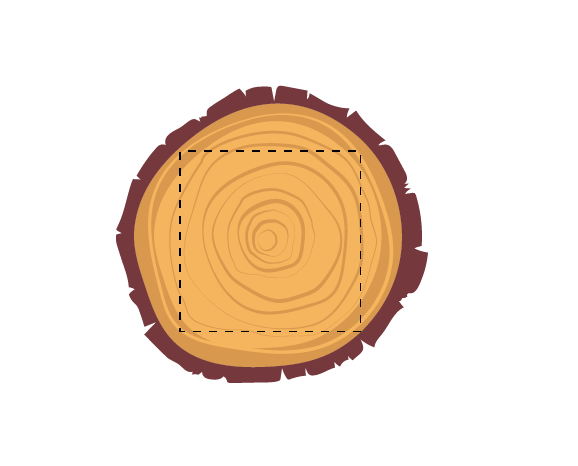

Boxed Heart Beam

Traditional and simple beam. The tensile and compressive stresses remain balanced (if the heart is centered) and long lengths hence remain stable.

Halved and Quartered Beams

Each beam will have a face with heartshake and contain unbalanced stresses and hence instability in long lengths. However, okay for short beams.

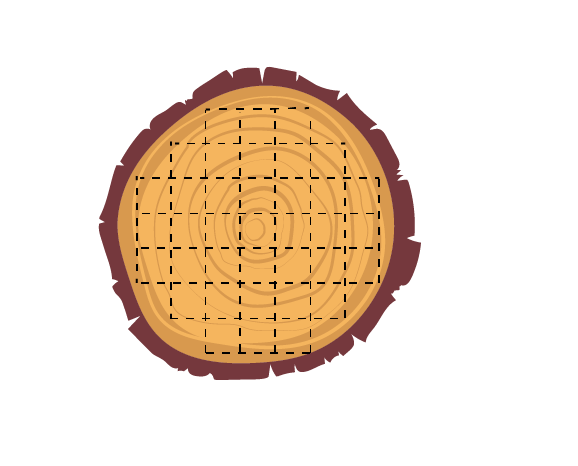

Small Section Beams

Good for long but small cross section beams. The sawing is relatively time consuming (expensive) and good quality (butt) logs are required.